Solution (Product)

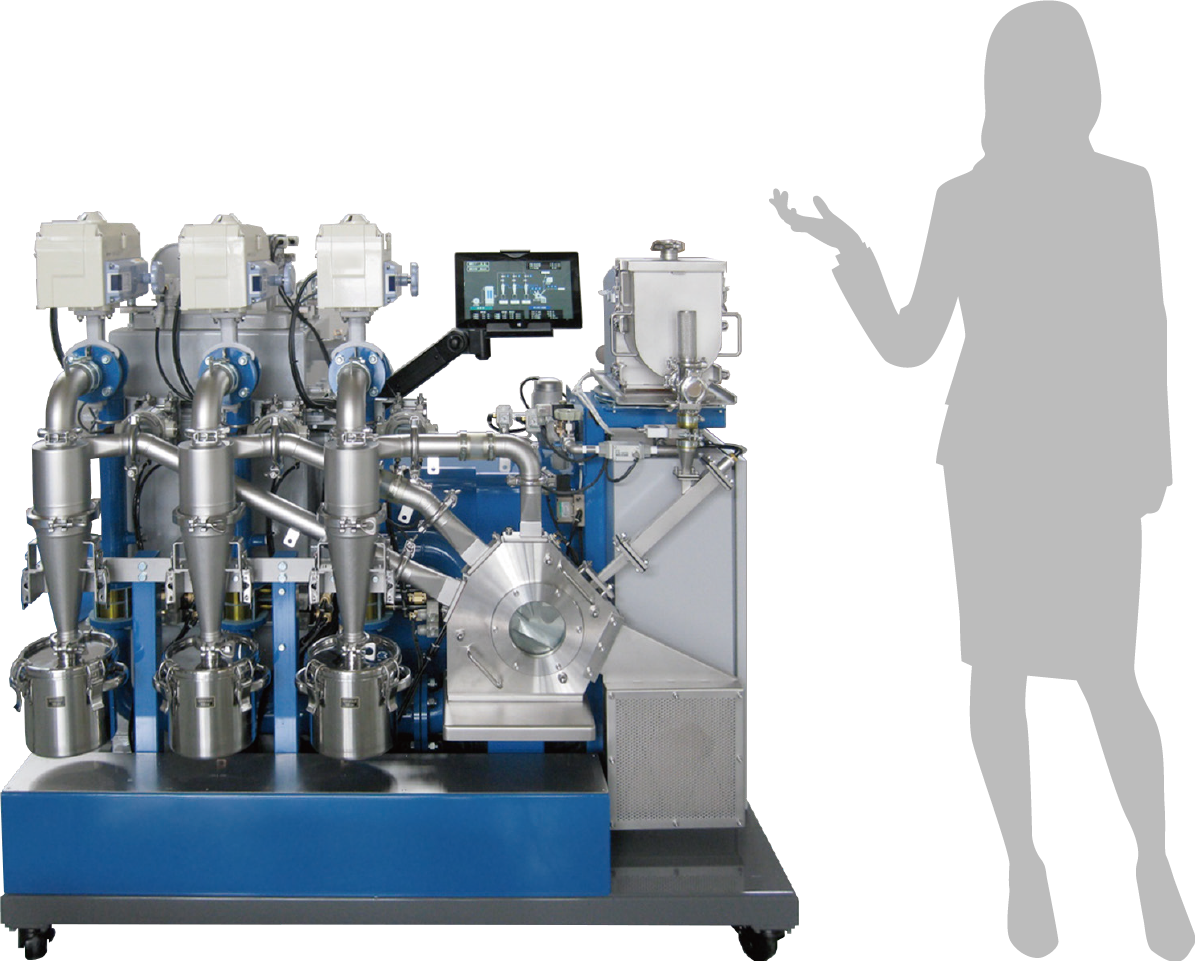

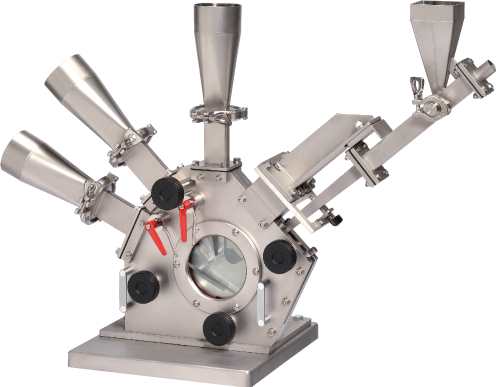

Coanda classifier

It enables to accurately classify micro fine powder range which screening machine cannot achieve.

Evenness of particle contributes to with development and production with high quality and high capability basis.

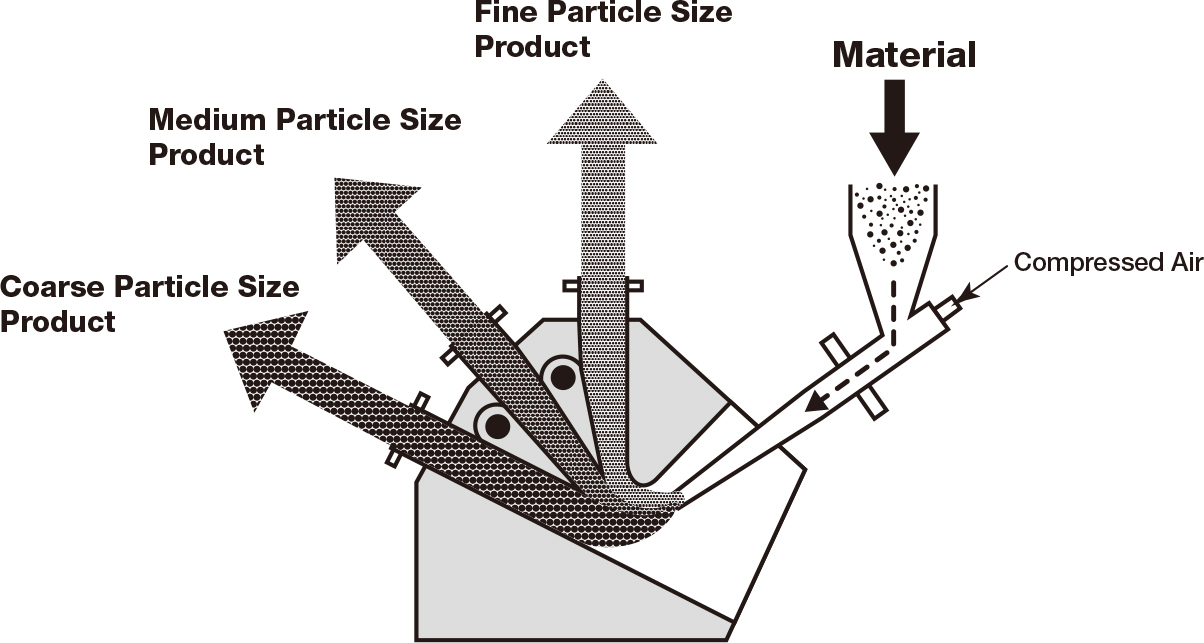

High Precision Coanda Classifier is an air current classifier which effectively obtains three different particle size products at one timeapplying the Coanda effect.

High dispersion nozzle of the material supplying part realizes highly efficient classification performance.

Even applicable to the classification of high adhesive or abrasive materials.

- Simple structure without driving parts.

- Extraordinal cost performance

- Easy cleaning and maintenance

- Classification ability applying high dispersion nozzle

- Classification size: 3μm ~ 200μm

- Throughput capability: 1 ~ 2000kg/hr

- Wear resistance parts is equipped as standard.

- Achieved closed circuit operation by inactive gas.

Please click here for more detail information.

Specifications

| Model | Throughput Capability |

Air Volume |

|---|---|---|

| HPC - ZERO | 1 - 10 | 1 - 4 |

| HPC - 1 | 20 - 150 | 5 - 10 |

| HPC - 2 | 40 - 300 | 8 - 16 |

| HPC - 3 | 60 - 450 | 10 - 20 |

| HPC - 4 | 80 - 600 | 14 - 28 |

| HPC - 5 | 100 - 750 | 16 - 32 |

| HPC - 6 | 120 - 900 | 20 - 40 |

| HPC - 9 | 180 - 1350 | 26 - 52 |

| HPC - 10 | 200 - 1500 | 32 - 64 |

| HPC - 12 | 240 - 1800 | 38 - 76 |

| HPC - 14 | 280 - 2100 | 44 - 88 |

| HPC - 16 | 320 - 2400 | 50 - 100 |

| HPC - 20 | 400 - 3000 | 62 - 124 |

The "Powder Lab" test equipment exclusively for High Precision Coanda Classifier is permanently installed in Kusatsu City, Shiga Prefecture, where we install HPC-ZERO and HPC-1 as test machine purpose.